Cutting-edge Solutions: Discovering the Convenience of Bulk Containers in Different Industries

Mass containers have arised as a critical advancement across numerous markets. Their layout improves storage and transport effectiveness, accommodating varied needs while advertising sustainability. Services in agriculture, production, and logistics report substantial enhancements in operational procedures. However, truth degree of their influence might not yet be fully understood. Exploring the various applications and benefits of mass containers can reveal insights that reshape market criteria. What lies ahead for this evolving solution?

Enhancing Agricultural Effectiveness With Mass Containers

Exactly how can mass containers transform agricultural practices? In the domain name of farming, bulk containers work as a pivotal development, enhancing effectiveness and sustainability. They make it possible for farmers to keep and transport large quantities of plant foods, seeds, and grains, minimizing the requirement for several smaller sized plans that often contribute to squander. By making use of mass containers, agricultural procedures can maximize their supply chains, decreasing managing prices and time. These containers are made for easy loading and unloading, enabling for quick shifts in between various stages of farming procedures.

Furthermore, bulk containers advertise better stock management, making certain that manufacturers have sufficient materials available without unwanted. This effectiveness translates to lowered labor costs and boosted productivity. In a sector commonly challenged by varying demand and seasonal variants, the dependability and scalability supplied by bulk containers present a considerable advantage, encouraging farmers to concentrate on top quality and yield.

Simplifying Manufacturing Processes Through Mass Solutions

Bulk options play a crucial duty in streamlining manufacturing processes by helping with efficient product handling and providing cost-efficient storage space choices. These containers aid maintain an orderly manufacturing atmosphere, inevitably boosting process and performance. As markets increasingly embrace mass solutions, they are likely to experience significant renovations in operational efficiency.

Effective Material Handling

Reliable product handling is important for enhancing production procedures, as it directly impacts efficiency and cost-effectiveness. Making use of mass containers can markedly simplify procedures by streamlining the motion and storage space of products. Their layout permits for very easy loading and unloading, decreasing the moment employees invest dealing with individual items. This performance not only lessens labor costs however also improves process, making it possible for suppliers to respond promptly to demand fluctuations. In enhancement, bulk containers advertise far better company within centers, helping with fast access to materials and reducing downtime. By implementing these versatile remedies, makers can boost overall operational effectiveness, guaranteeing that assembly line run smoothly and effectively while decreasing waste and resource expenditure. As a result, bulk containers play an essential function in boosting product handling methods.

Affordable Storage Space Solutions

As makers seek to optimize their procedures, cost-efficient storage space solutions come to be progressively important. Mass containers give a sensible methods of keeping big quantities of materials, reducing the requirement for several smaller sized storage units. This consolidation brings about decrease supply costs, as bulk containers commonly need much less handling and lead to decreased labor expenditures. On top of that, their standard sizes facilitate efficient piling and storage, maximizing storehouse space. By using mass containers, makers can reduce waste and enhance the overall organization of their centers. These containers are likewise developed for longevity, which can decrease substitute prices over time. Generally, incorporating mass containers into storage space techniques enables manufacturers to simplify operations while keeping productivity and performance in their supply chains.

Boosted Production Process

Making use of bulk containers greatly enhances production workflows by simplifying the administration of products throughout the production procedure. These containers facilitate efficient storage and transportation, minimizing the moment invested on handling products. Therefore, manufacturers can attain quicker turnaround times and decrease delays in manufacturing. Mass containers also promote far better company, permitting groups to conveniently access basic materials when needed, which even more streamlines procedures. Additionally, the standardized shapes and size of these containers make it possible for optimized use warehouse space, adding to total performance. By incorporating bulk remedies right into their procedures, business can improve stock control and reduce waste, inevitably resulting in enhanced productivity and a more nimble manufacturing environment.

Revolutionizing Food Service Logistics

The food service market is undertaking significant makeover with the adoption of mass containers, boosting storage abilities and enhancing space use. Reliable storage services make it possible for organizations to take care of stock better, while streamlined transport processes reduce expenses and enhance distribution times. As an outcome, these innovations are improving logistics and driving higher efficiency throughout the sector.

Effective Storage Solutions

Innovative storage space services are transforming food service logistics by improving efficiency and enhancing room usage. Mass containers, made for maximum ability, enable food provider to decrease lost room while keeping easy access to products. These containers can be piled and arranged according to stock requirements, improving the storage procedure. Furthermore, their durability guarantees that foodstuff stay secure and secure, minimizing spoilage and losses. With features such as modular styles and compatibility with different shelving systems, these containers can adjust to diverse kitchen formats. By employing reliable storage space options, food service operations not just improve operations however likewise improve total performance, guaranteeing that resources are utilized properly to meet client needs.

Structured Transport Processes

While lots of factors add to the efficiency of food solution logistics, streamlined transport procedures play an essential role in optimizing supply chain operations. The adoption of mass containers substantially boosts the motion of items, permitting for quicker loading and dumping at circulation. Their standard dimensions facilitate reliable stacking and storage space, decreasing wasted space throughout transit. In addition, bulk containers reduce the requirement for too much packaging, resulting in decrease costs and decreased ecological impact. By making certain that products are safely transferred, they mitigate damage and perishing, which is important in the subject to spoiling food sector. On the whole, the assimilation of mass containers into transport approaches not only boosts operational performance but additionally sustains lasting techniques within the food service industry.

The Duty of Bulk Containers in Drug Supply Chains

In the pharmaceutical sector, mass containers play an important duty in guaranteeing the effective and safe transportation of raw products and finished products. These containers are particularly developed to satisfy rigid regulative demands, offering suitable defense against contamination and deterioration during transportation. Their durable building and construction permits for the protected transportation of delicate materials, such as energetic pharmaceutical active ingredients (APIs) and intricate formulations, while reducing the danger of damages.

Mass containers promote structured handling and storage procedures within stockrooms and manufacturing facilities. Their standard sizes enable compatibility with automated systems, boosting performance and decreasing labor prices. By utilizing bulk containers, pharmaceutical companies can you could try here attain significant cost financial savings via bulk acquiring and minimized product packaging waste.

Promoting Sustainability in Product Packaging Practices

The pharmaceutical market's increasing reliance on mass containers has actually motivated a more comprehensive assessment of sustainability in packaging techniques throughout numerous sectors. As companies look for to minimize their environmental effect, cutting-edge techniques to packaging have actually gotten grip. Mass containers, made for reuse and recycling, offer a sensible solution. Their longevity expands item lifecycles, lessening the demand for single-use packaging.

The shift towards green finishings and biodegradable materials has become important in the design of these containers. This adjustment not just addresses waste reduction however also straightens with customer need for lasting items.

Industries such as food and cosmetics are taking on similar strategies, identifying that lasting packaging can boost brand reputation. Collective campaigns in between manufacturers and suppliers even more promote sustainability, urging the read more advancement of closed-loop systems - used collapsible bulk containers. Ultimately, welcoming lasting product packaging techniques is important for promoting a circular economy and alleviating the ecological impact across diverse markets

Cost-efficient Transportation Solutions With Bulk Containers

Bulk containers simplify taking care of procedures, leading to reduced labor prices and reducing the risk of damages during transit - used collapsible bulk containers. Industries such as agriculture, chemicals, and drugs take advantage of the longevity and robustness of these containers, which can withstand extreme problems while making sure the stability of their contents

Moreover, the multiple-use nature of mass containers adds to long-term cost savings, as companies can count on fewer, more durable devices as opposed to regularly replacing single-use packaging. In this method, mass containers not just improve effectiveness but also sustain general cost management in supply chain procedures.

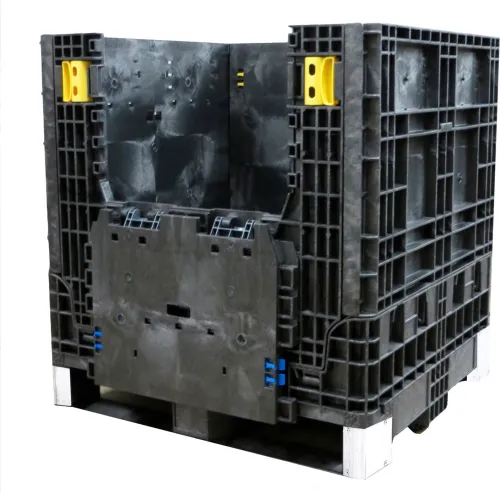

Modification and Flexibility wholesale Container Layout

While many bulk containers are designed for basic applications, their customization and versatility have actually ended up being vital functions for sectors with one-of-a-kind demands. Suppliers currently provide a series of options, permitting clients to tailor containers to certain dimensions, products, and performances. This flexibility allows companies to enhance storage space and transport processes, making sure compatibility with numerous handling systems.

The food and pharmaceutical industries often require containers that satisfy rigid health and safety standards. Customized styles may include features such as tamper-proof seals, easy-to-clean surfaces, and specialized ventilation systems. In the farming sector, bulk containers can be tailored to promote the transport of diverse commodities, from grains to liquids, improving functional effectiveness.

Eventually, the capacity to customize bulk containers not only boosts productivity yet likewise supports sustainability efforts by decreasing waste and maximizing resource use throughout numerous fields. This adaptability placements bulk containers as versatile remedies in today's vibrant market.

Often Asked Inquiries

What Products Are Mass Containers Generally Made From?

Mass containers are commonly made from products such as high-density polyethylene (HDPE), polypropylene, steel, or aluminum. These products supply longevity, resistance to chemicals, and the ability to safely store and transfer different items throughout industries.

How Are Bulk Containers Cleaned Between Uses?

Bulk containers are generally cleaned making use of high-pressure cleaning, vapor cleaning, or chemical sanitization methods (used plastic containers). The cleansing process warranties that residues are eliminated, avoiding contamination and preserving the high quality of contents for subsequent usages

Can Mass Containers Be Reused Several Times?

Yes, bulk containers can be reused several times. Their robust layout permits duplicated use across various applications, given they are effectively cleansed and kept after each use to guarantee safety and hygiene requirements.

What Are the Weight Purviews for Bulk Containers?

Weight restrictions for bulk containers generally vary from 1,000 to 3,000 pounds, depending upon the material and style. Requirements may differ by maker, so it is essential to consult guidelines for particular container kinds.

Are There Basic Dimensions for Mass Containers?

Yes, there are standard sizes for mass containers, typically varying from 20 to 40 cubic feet. These measurements facilitate efficient storage and transport throughout different markets, ensuring compatibility with equipment and maximizing space utilization.

Using bulk containers can significantly streamline operations by simplifying the motion and storage of materials. In enhancement, mass containers promote far better organization within facilities, facilitating quick accessibility company website to products and decreasing downtime. Bulk containers supply a useful ways of keeping big quantities of materials, minimizing the need for multiple smaller storage space units. The food service industry is undertaking substantial makeover via the adoption of bulk containers, boosting storage abilities and optimizing space application. Mass containers assist in streamlined handling and storage space operations within storehouses and manufacturing facilities.